Industrial Automation—Increased Efficiency and Higher Quality

Industrial Automation is the key to higher efficiency, consistent quality and reduced costs in modern manufacturing. Our company has been a reliable partner for many years in exactly these areas.

Find out more about the background to industrial automation, our approach and specific examples here.

We Are Your Partner for Industrial Automation

- 20 Locations Worldwide

With over 30 years of experience, an extensive project portfolio and experienced engineers, we are a reliable partner for companies worldwide. Our headquarters are in Germany. Our global presence with more than 20 locations enables us to operate both locally and internationally.

- Close Cooperation in Development

We work closely with our customers' engineering teams to analyse processes and identify automation potential with the highest ROI. We realise solutions that sustainably increase efficiency and competitiveness.

- Customized Automation Systems

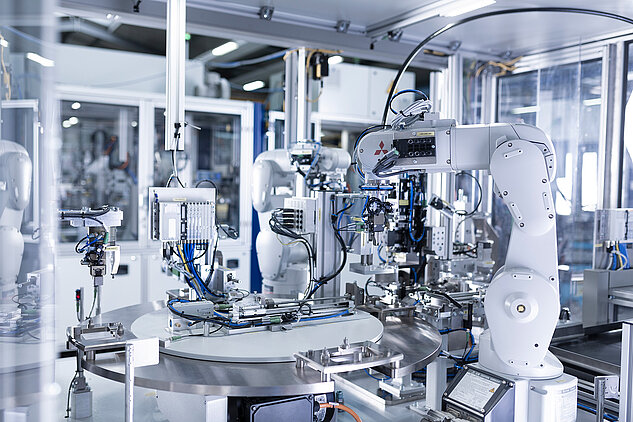

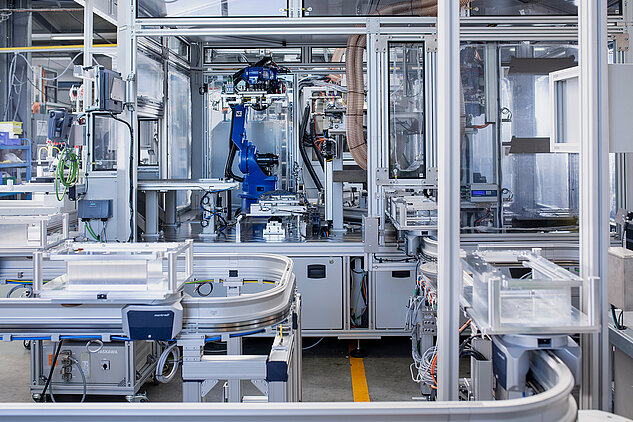

Our automation solutions are tailored precisely to the specific requirements of our customers. We are independent of individual manufacturers. Our modular concepts enable us to supply semi-automatic and fully automatic production lines according to requirements.

Two Examples for Industrial Automation

MedTech

Medical devices often consist of several complex components that are manually assembled by the operator. This makes them prone to errors. In this customer project, we developed an automated system that counts and bands medical diagnostic test cards. This not only speeded up the process, but also made it much more efficient.

Electronics

The data center market is rapidly growing, which demands highly efficient and reliable heat exchangers. The HAHN Automation Group developed a solution that not only automates the tube rolling process, but also improves efficiency and quality. The automated solution will complete a 3000 tube vessel in roughly ½ the time it takes to complete manually.

The Project Process at a Glance

- Analyzing Potential for Automation

Collaboration with the customer begins with an analysis of the potential of existing production processes. Together with the customer, our team of experts evaluates the current production environment, identifies manual processes and checks which areas are suitable for automation. The focus here is on precision, increased efficiency and the best possible return on investment. More about our potential analysis in automation.

- Automation Concept

After the analysis, we develop a customized automation concept. We select the appropriate technologies, define the degree of automation and customize the system to the individual requirements. Our aim is to develop an optimized solution that seamlessly integrates existing processes and creates long-term added value.

- Realisation of The Project

As soon as the concept is finalized, the implementation follows. Our engineering teams design and manufacture the automation solution, test it extensively and accompany the commissioning at the customer's premises. By working closely together, we ensure that the new system functions optimally and fulfills all requirements. Even after implementation, we offer comprehensive support and assist the customer with further optimizations.

From the Concept Idea to Realization and Customer Service—We Provide Everything from a Single Source

As an Industrial Automation company, we see our central role as being an integrator. We utilize the technology that is best suited to our customers' solutions, regardless of the manufacturer. We can map complete process chains and aim to have a central point of contact for every customer project. In this way, we reduce the complexity of communication.

Frank Konrad, CEO

Frequently Asked Questions about Industrial Automation

What Is Industrial Automation (Definition)?

Industrial automation refers to the use of machines, robots and digital control systems to optimise production processes. Manual processes are replaced or supplemented by automated solutions in order to achieve greater efficiency, consistent quality and lower operating costs. Modern automation systems integrate sensors, AI and IoT technologies to monitor and adapt processes in real time. This results in more precise, faster and more flexible production processes that make companies more competitive.

What Are the Advantages of Industrial Automation for a Company? Why Is It Worthwhile?

Industrial automation increases efficiency, reduces errors and ensures consistently high quality. Automated processes shorten cycle times and reduce operating costs as there is less waste and rework. At the same time, space-saving automation solutions optimise production space requirements. Modern systems can be flexibly customised so that companies can react more quickly to market developments. Automation also increases occupational safety by allowing machines to take over dangerous or physically demanding tasks.

Which Robot Systems Are Used in Automation?

Various robot systems are used in industrial automation, which are selected specifically according to requirements. Here are a few examples: Industrial robots perform precise tasks such as welding or assembly, while collaborative robots (cobots) work flexibly with humans. SCARA and Delta robots are ideal for fast assembly and packaging processes, while gantry robots are used for precise material handling. Automated guided vehicles (AGVs and AMRs) optimise the internal material flow. The right combination of these systems creates efficient, flexible and cost-saving automation solutions.

What Is the Connection Between Industrial Automation and Industry 4.0?

Industrial automation is the basis for Industry 4.0, as it connects machines and robots with digital technologies. Sensors, IoT and AI enable automated systems to collect and analyse data and adapt flexibly. This enables self-optimising production with greater efficiency, predictive maintenance and optimised use of resources. Companies benefit from greater transparency, reduced downtimes and more intelligent control of their production processes.

Contact Us

Are you ready to discuss your next project? Let our experts answer any questions you may have. Please use the contact form, and we will get back to you as soon as possible.