HAHN Automation Group enables shift to an automated tube rolling process

The data center market is rapidly growing, which demands highly effiecient and reliable heat exchangers. The HAHN Automation Group developed a solution that not only automates the tube rolling process, but also improves efficiency and quality.

#Electronics #TubeRolling #HeatExchanger #Automation

- Outdated methods to modernized solution

- Reduced defects and NOK parts

- High article variety possible

Challenge

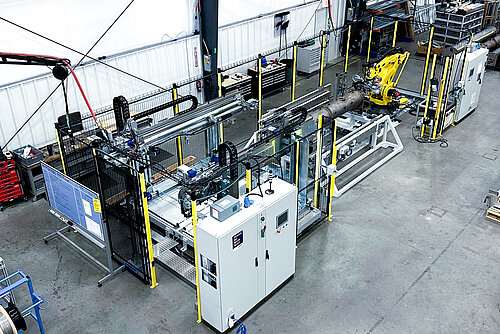

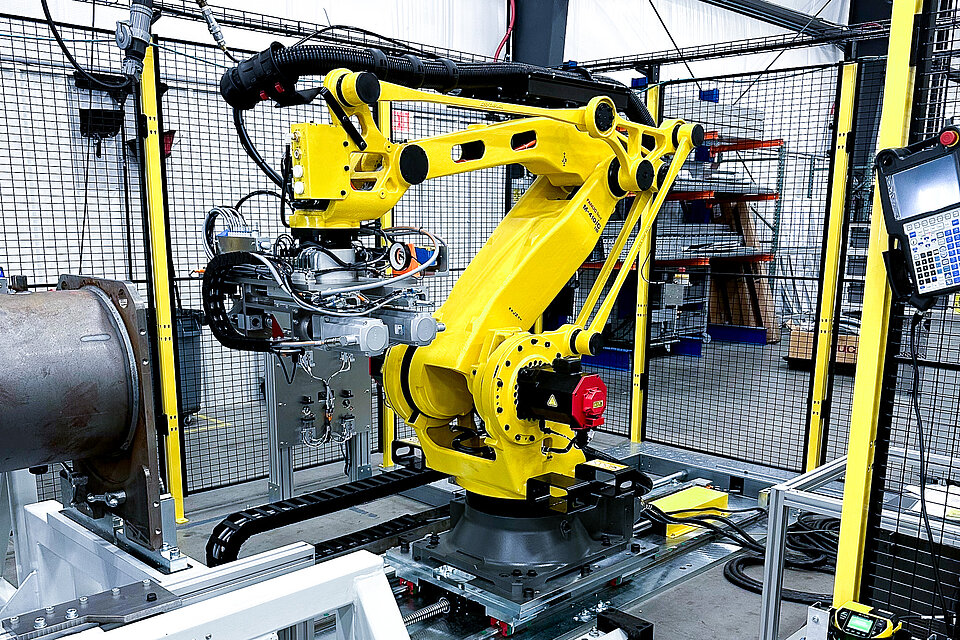

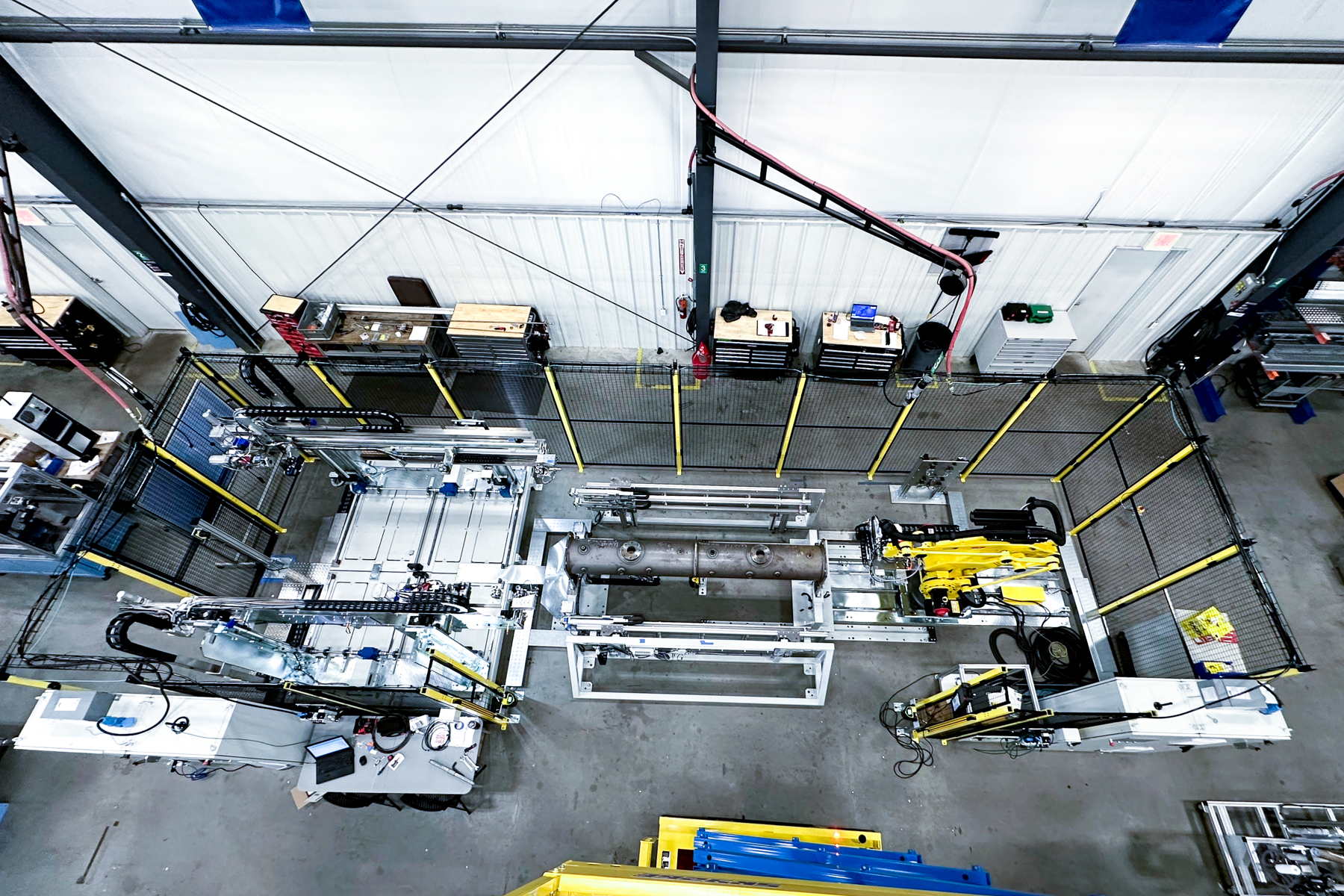

The customer faced significant inefficiencies in their heat exchanger tube rolling process, including slow production, high leakage rates, and labor-intensive manual operations. This was particularly problematic given the rapidly growing data center market, which demands high-efficiency, reliable heat exchangers. Traditional pneumatic rolling systems were outdated, inflexible, and couldn't keep up with the need for customized solutions and increased output. The core challenge was to modernize and automate the tube rolling process to meet the demands of a rapidly expanding market while improving efficiency and quality.

Developing a Solution

The core of the solution was a shift to a modernized and highly precise tube rolling process. Outdated methods were replaced with servo-driven spindles, providing exceptional control over the rolling process. This allowed for precise adjustments in pressure and speed, dramatically reducing defects and ensuring consistent, high-quality tube expansion. To further enhance accuracy and flexibility, high-resolution camera systems were integrated. These systems enabled precise tracking and location of the rolling points, allowing the system to adapt to variations in tube placement and heat exchanger geometries, crucial for handling diverse and custom designs. Essentially, the solution leveraged servo technology and advanced vision systems to transform the tube rolling process, significantly improving efficiency and quality.