HAHN Automation Group Improves Medical Diagnostics Production with Automated Banding

A medical diagnostics manufacturer, let’s call them “Alex,” was looking to further automate a process that involved counting and banding diagnostic test cards. We designed a fully-automated machine that eased the burden of manual unloading and brought accuracy to the counting and banding processes.

#MedTech #Banding #IMM #Servo #Robotics

- Manual process to fully-automated

- Improved accuracy and repeatability

- Increased quality control

Challenge

Alex needed a way to bring automation to their diagnostic test card counting and banding process. Their existing procedure involved an operator manually loading a vertical stacking machine in order to estimate the count before manually banding the stack of cards. Due to the fragile nature of the cards, this process was meticulous—the operator had to ensure the cards were secure without causing damage. Additionally, the operator did not have a way to guarantee that each stack contained the same number of test cards. Amidst growing demand for the product, an operator-dependent process was no longer an option for Alex.

Developing a Solution

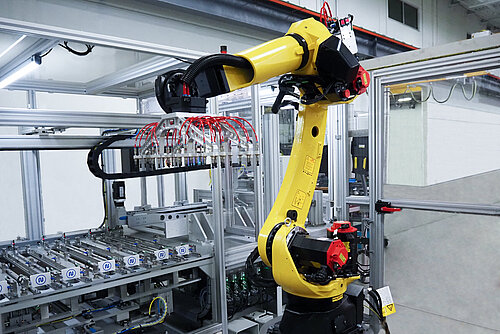

The HAHN Automation Group proposed a system comprised of two identical stations surrounding the customer’s existing injection mold machine (IMM). Each system involves a robot that removes the product from the IMM and loads it into the counting and banding station. The system is compatible with multiple robot OEMs, this particular one us using Fanuc and Kuka, which can add to the level of flexibility. The test cards are automatically counted and banded into stacks of exactly 105 cards on a horizontal surface that is easier for an operator to then remove.