Reconfigurable System Allows for Flexible Testing of Multiple Product Variations

HAHN Automation Group provides a multi-station, semi-automated system with complete flexibility of configuration. A catheter manufacturer was looking to create a multifunctional, flexible system for the research and development of neurovascular device coating and curing.

#automation #MedTech #catheter #testing

- Fully customizable system

- From manual operations to semi-automated

- Consistent and accurate results

Challenge

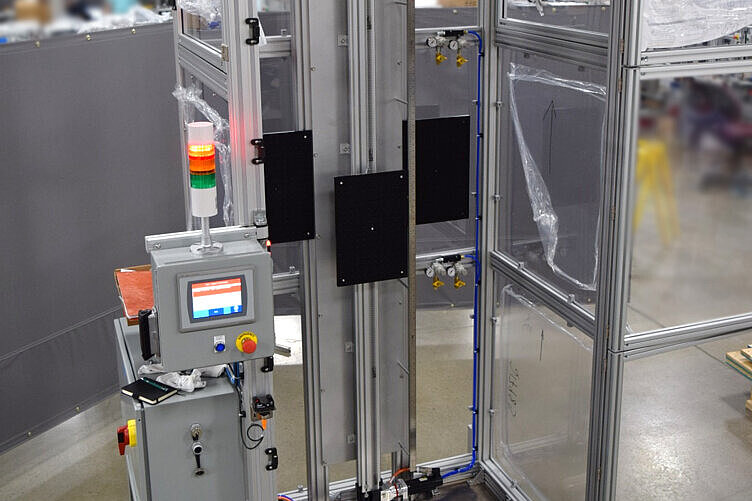

A catheter manufacturer was looking for development equipment to be used in their research lab. They wanted the capability to test and analyze the coating and curing process of a variety of materials across products of differing lengths. Most of the details of the tests were kept confidential, but they included adjusting factors such as product height, curing temperature, coating and curing duration, and UV intensity.

For research and development purposes, the equipment needed to be flexible and easily adaptable. That said, like production equipment, the team had to adhere to strict safely and quality protocols. Additionally, the team wanted to implement details that would ensure tests were run consistently across different operators and shifts.

Developing a Solution

Prior to our solution, the customer had designed and built a version of their desired solution but found they needed something more robust with features that would allow for better consistency during the testing process.

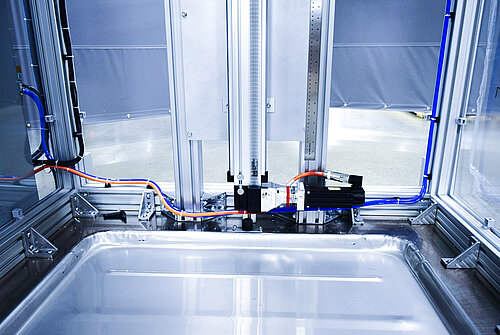

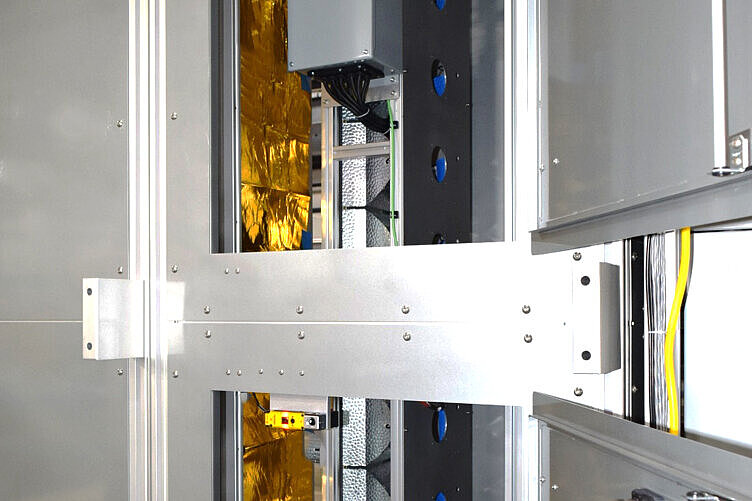

The coating station has slides and breadboards that allow the customer to attach custom tooling made by the HAHN Automation Group and/or their own tooling and completely configure the setup to their individual tests. During the coating process, this flexibility allows the customer to experiment with techniques for applying the coating to their product.

Additionally, while the station is fully customizable, it includes a measuring scale that helps accurately set dimensions across multiple test sequences. Once the product is coated, an operator transfers it to the curing system.