HAHN Automation Group Employs Lean Cell Technology in Assembly Line Approach for Semi-automated Equipment

Medical devices often involve multiple, complex sub-assemblies that are operator dependent—leaving them prone to error. In this example, you can learn about how we helped a medical device manufacturer leverage semi-automated equipment to reduce this risk throughout the assembly, test, and inspection processes within their manufacturing.

#automation #MedTech #surgical #semiautomated

- Transition from operator-dependent to semi-automated

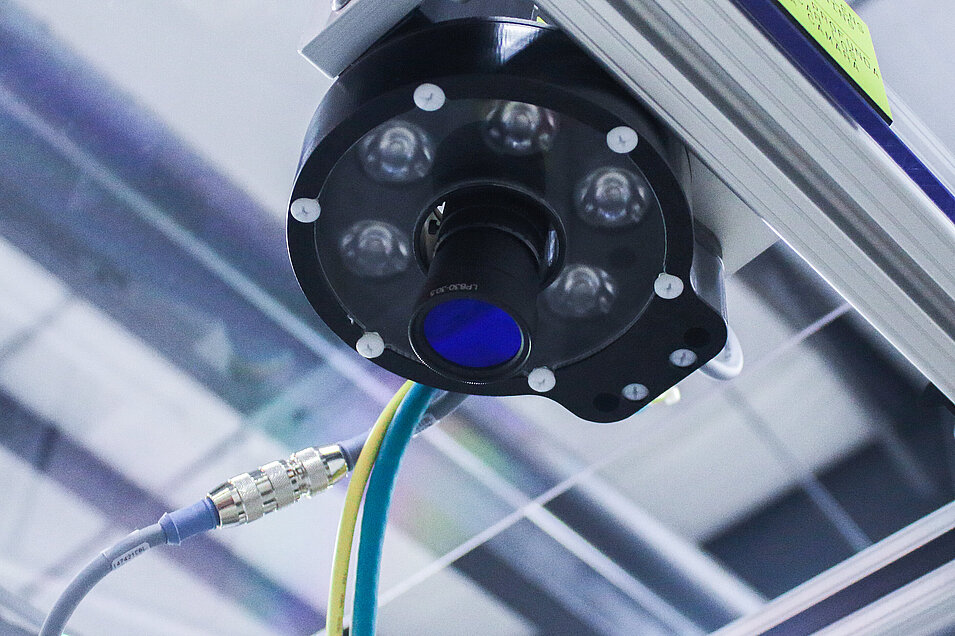

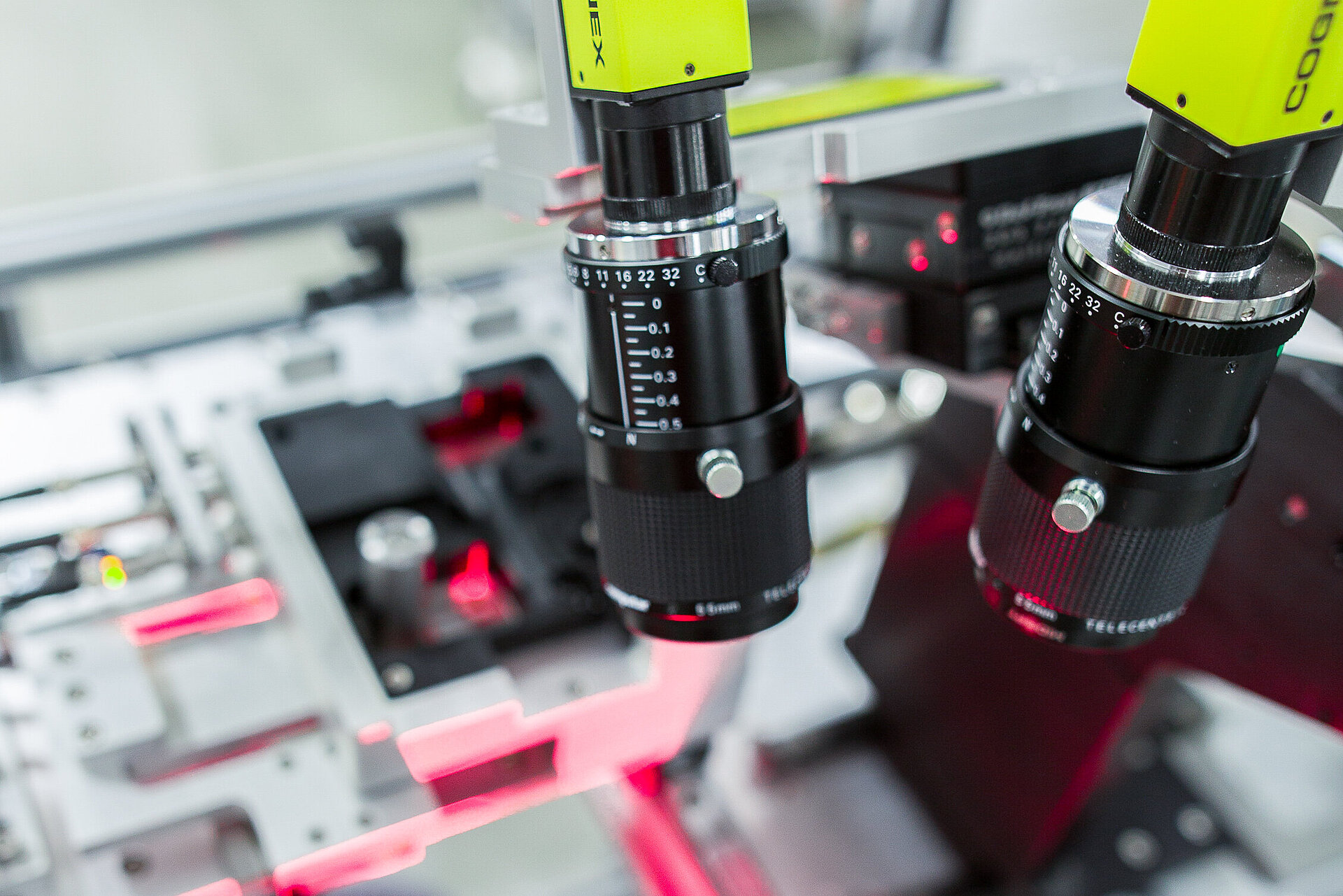

- Incorporate machine vision for inspection

- Leverage robust inline and EOL testing

Challenge

A large surgical device manufacturer needed a system that would assemble, test, and label their latest product—comprised of multiple shaft, handle, and jaw sub-assemblies. Using in-process checks, they wanted to verify that all components in the final assembly complied with rigid quality standards; additionally, recorded data from post-process testing operations was required on all of the devices.

Developing a Solution

We developed semi-automated equipment using lean cell technology in an assembly line approach—incorporating a manually indexing, pallet conveyor to transfer assembled components between operations.

While the previously manual assembly of this device was prone to operator errors, this new system inspected components throughout the assembly process while the device was being held in dedicated fixtures.

The new system also offered a self-calibration routine on the test processes that automatically calibrated the monitoring equipment during scheduled intervals. Post-process testing was included in the assembly cell to verify that the device was in compliance before being laser marked for traceability.