HAHN Automation Group Helps Catheter Manufacturer Automate Previously Manual Coiling Process

Increases in product demand often drive the need for manufacturers to transition from a manual process to an automated one. In this example, you can learn about how we helped a medical device manufacturer incorporate automation into their once tedious process. We will call this customer "Oli.” Oli, a vascular catheter manufacturer, was struggling to produce consistent results in a highly complex, manual sub-assembly of their device.

#automation #MedTech #vascular #catheter

- Transition from manual to automated process

- Produce repeatable, accurate results

- Reduce cycle time and footprint of assembly

Challenge

Oli’s previous coiling process called for operators to manually coil a delicate, 0.002”-0.003" thick and 0.020" wide, wire around the exterior of a mandrel at a specified pitch. Doing so required multiple operators to feed, wind, clamp, coil, and cut the material before transferring the device to a welding station—all of which was done by hand leading to long cycle times, inaccuracies, and inconsistency between operators.

Developing a Solution

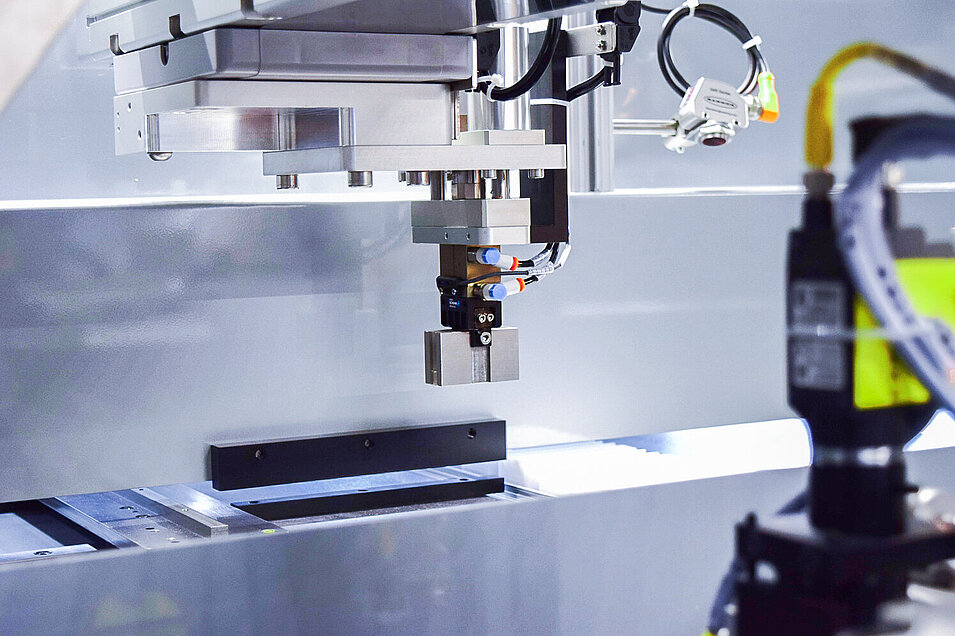

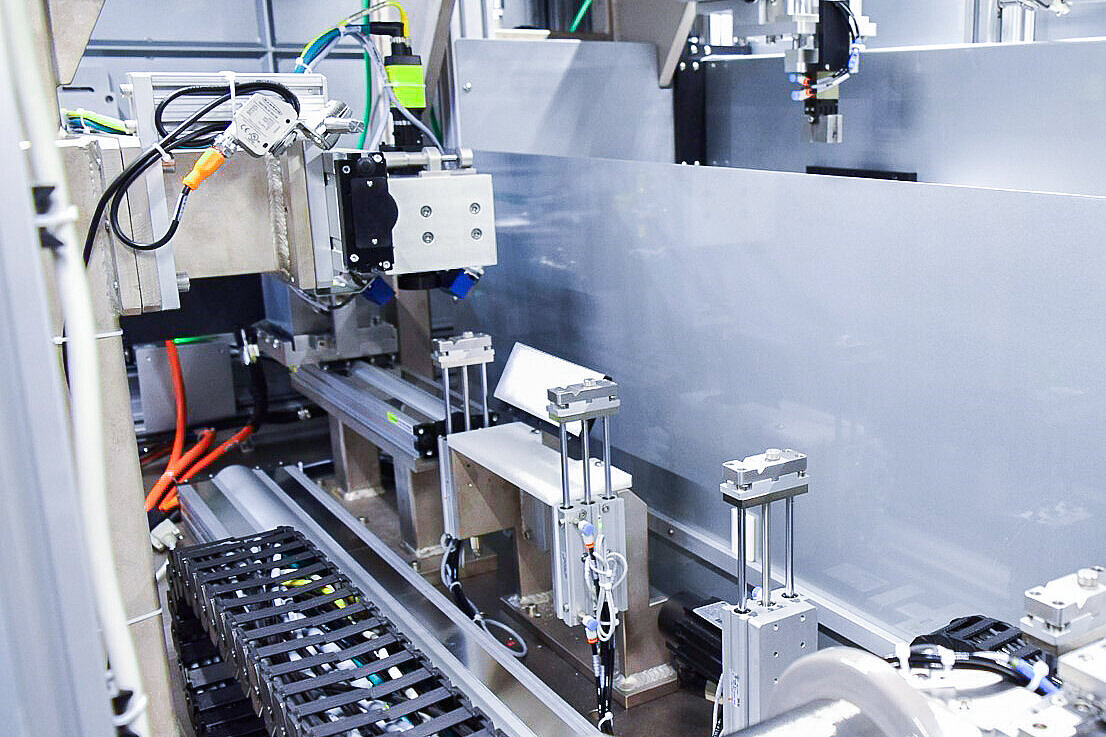

Our engineering teams worked closely with the customer to assess their process, environment, and operators. This allowed us to determine which parts of the process would lend themselves to automation as well as where the customer would see the greatest ROI. Ultimately we designed and built a fully-automated system that would allow operators to load multiple mandrels at once, secure the device, wrap the mandrel with coils of precise spacing, and secure the final product with welding—all inside of the same machine.