Comprehensive Automation Solutions for Industrial and Automotive Electronics

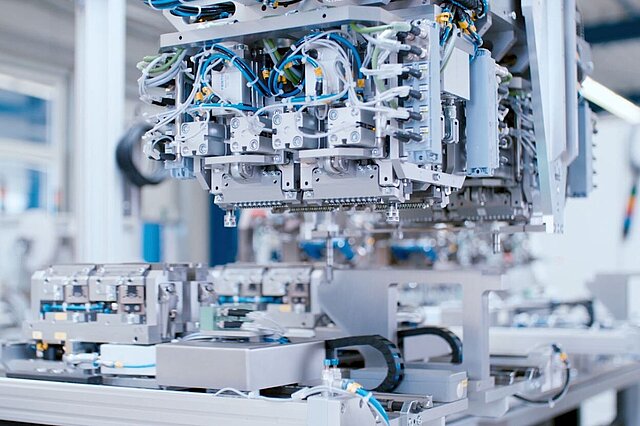

The HAHN Automation Group specializes in providing cutting-edge production solutions for many essential electronic components.

Our many years of expertise in insert molding enables us to offer custom automation and handling solutions for industrial and automotive electronics companies. We specialize in hybrid plastic components with metal inserts with exacting tolerances and superior material compatibility while providing end-to-end solutions for your insert molding requirements.

We offer optimal system solutions that seamlessly integrate into your manufacturing process. From handling raw materials like pins or terminals, to the final packaging stage. Our support extends from the initial design phase of new products, ensuring they are optimized for automation.

Scaling Automation to Meet Your Needs

Automated, semi-automated, or manual—we ask the right questions to design and build a system that supports your production goals, environment, and staff. Our custom material handling, test, and inspection equipment can help you:

- Produce a new product.

- Improve the manufacturing process.

- Decrease rejected material.

- Increase production capabilities.

- Integrate product changes.

- Accelerate development.

Automation and Assembly Portfolio

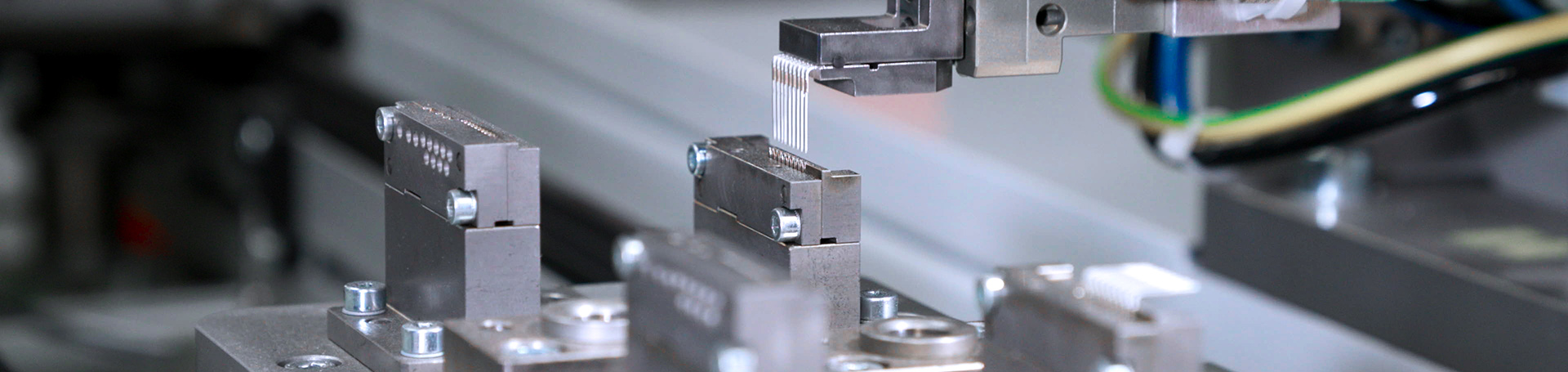

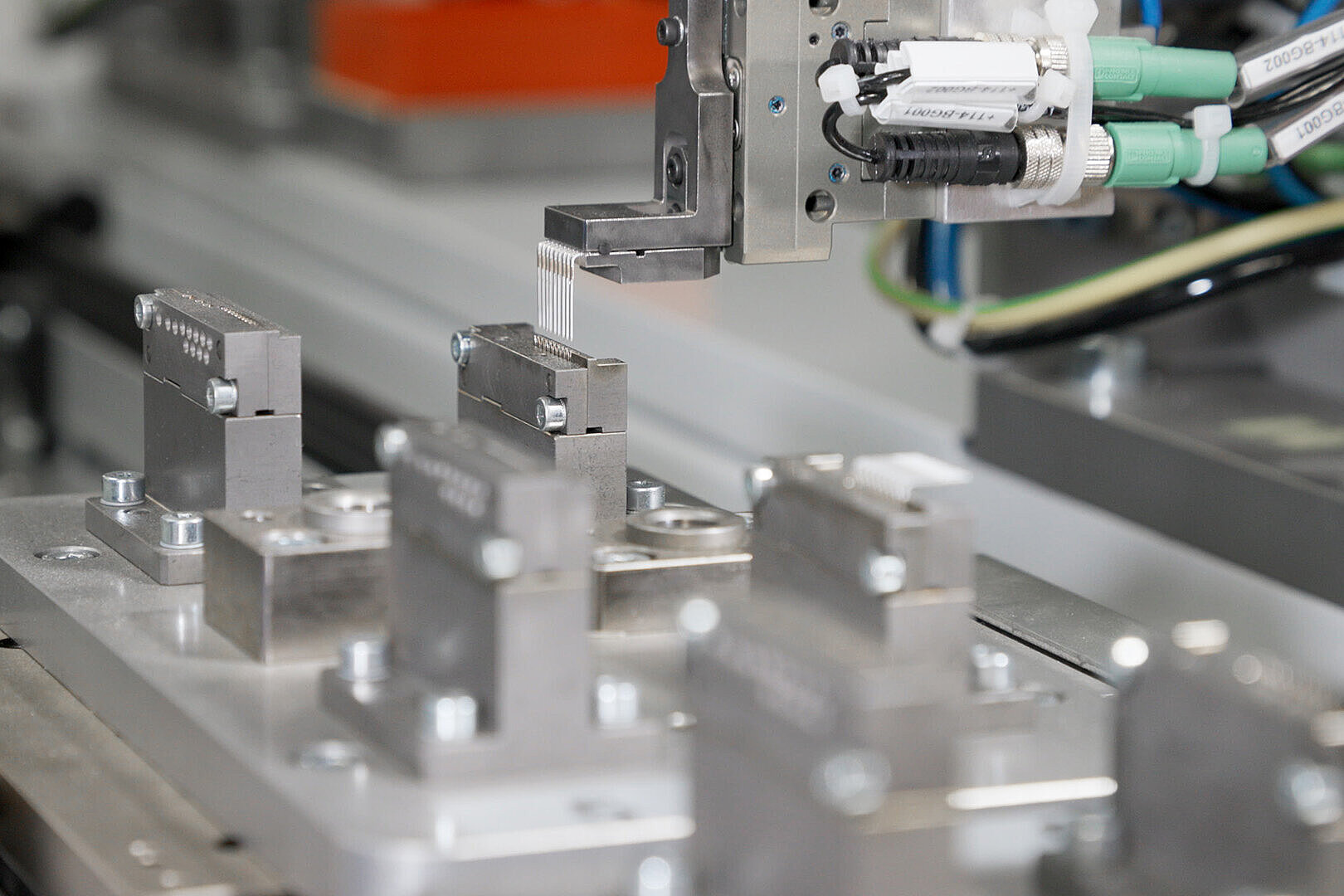

Connectors

Reliable connectivity is vital in today's interconnected world. Our production solutions for connectors ensure seamless communication and power transmission in various systems. We provide customized production solutions for a broad spectrum of connector types tailored to your specific requirements.

Miniaturization in Automotive Technology

As vehicles become increasingly feature-rich and automated, a multitude of electronics competes for limited space within densely packed vehicle architectures. Miniaturized connectors offer a key advantage by enabling the integration of more components into confined spaces, enhancing functionality without sacrificing size or weight. The resulting challenges, such as component fragility and size constraints, pose significant automation considerations.

Relevant Technology

- Material feeding & separation

- Preparing inserts

- Injection Molding Machine (IMM) process

- Assembly systems

- Test systems including insulation and continuity testing, visual inspection e.g. swash circumference

- Laser marking & labeling

- Packaging

Electronics Housings

Electrical housings are engineered to provide robust protection for sensitive electronic equipment while ensuring efficient heat dissipation and ease of access for maintenance. Meeting stringent manufacturing standards, electrical housings must be inherently waterproof and be engineered to withstand even the most challenging environmental conditions.

Relevant Technology

- Material feeding & seperation

- Preparing inserts

- Injection Molding Machine (IMM) process

- Assembly systems

- Test systems including insulation and continuity testing, visual inspection, e.g. swash circumference

- Laser marking & labeling

- Packaging

Busbars

Busbars are pivotal for efficient power distribution across diverse applications. Our production solutions ensure reliability and high performance. Whether it's for industrial machinery or electrical systems like high performance batteries or drives of electrical vehicles (EVs). In addition to facilitating power conduction and distribution, busbars play a crucial role in thermal management within EVs. Without busbars, EVs may be susceptible to overheating due to the significant heat generated within the battery system.

Relevant Technology

- Material feeding & seperation

- Pre-heat of inserts

- Injection Molding Machine (IMM) process

- Assembly systems

- Test systems including insulation and continuity testing, visual inspection, e.g. swash circumference

- Laser marking & labeling

- Packaging

Coils and Coil Formers

Coils and coil formers are essential components used in various industries, such as Electronics,, Automotive, and HVAC, for applications like transformers, motors, valves, and solenoid switches. Our solutions ensure precision and reliability in coil manufacturing processes.

Relevant Technology

- Material feeding & seperation

- Preparing inserts

- Injection Molding Machine (IMM) process

- Assembly systems

- Test systems including insulation and continuity testing, visual inspection, e.g. swash circumference

- Laser marking & labeling

- Packaging

Connection Solutions

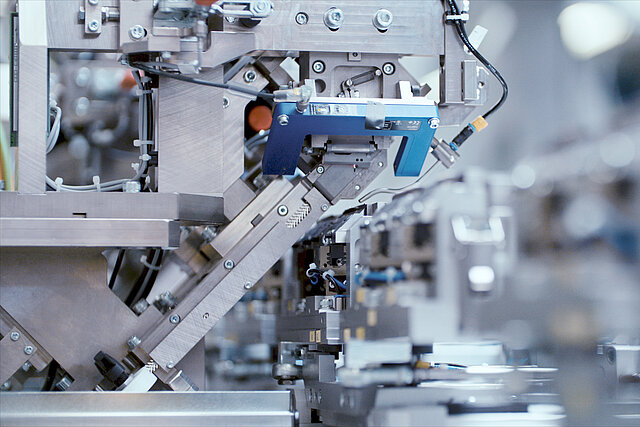

Wire-to-Board

Wires from a component or device link to a connector mounted on a circuit board, facilitating straightforward and secure attachment to other components or devices on the board.

Board-to-Board

Directly linking two separate circuit boards or electrical components, typically through connectors or interfaces, enables communication and data transfer between the circuits, facilitating integrated functionality or modular assembly in electronic devices.

Contact Us

Are you ready to discuss your next project? Let our experts answer any questions you may have. Please use the contact form, and we will get back to you as soon as possible.